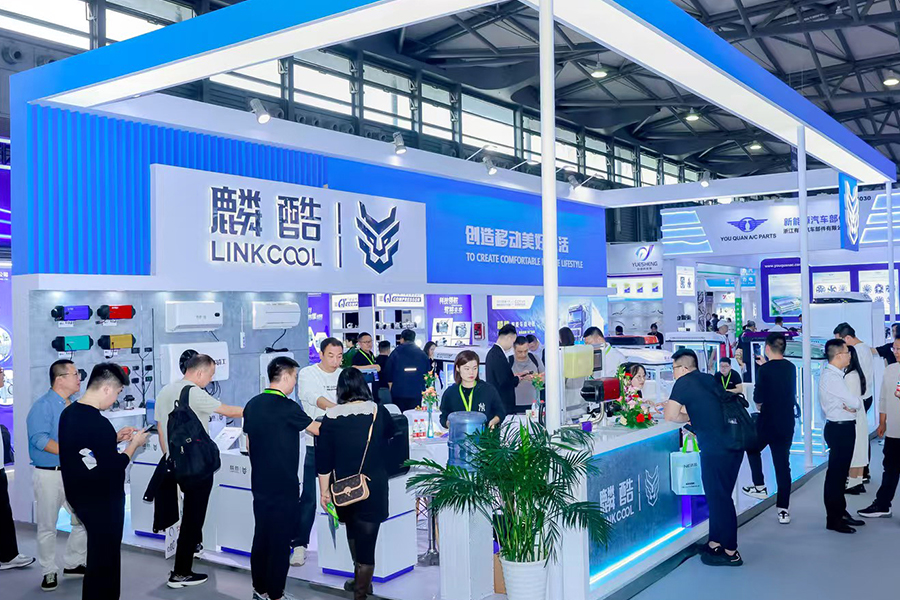

Zhejiang Linkcool Technology Co., Ltd. is China Truck Air Conditioner Manufacturer and Sale Truck Air Conditioner Factory. It focuses on the research, development, production and sales of automotive new energy appliances. Its main products include parking air conditioners, parking heaters and car water dispensers. As an integrated industrial and trade enterprise, we are committed to providing customers with high-quality, high-performance automotive appliances and outdoor camping appliances. We have more than 800 after-sales service outlets across the country.

Zhejiang Linkcool Technology Co., Ltd. covers an area of 20,000 square meters, providing employees with a spacious working environment. It currently has more than 150 employees and a professional R&D team and production team. We actively conduct technical exchanges and cooperation with industry experts and partners to jointly promote technological progress in the industry.

The primary difference between truck air conditioning and regular vehicle systems is the size and cooling capacity. Truck air cond...

View MoreRV air conditioners have several notable shortcomings. One major limitation is their high power consumption. RV AC units typically...

View MoreIn recent years, 12V air conditioners have become increasingly popular for a variety of applications, from cooling vehicles and RV...

View MoreEnergy efficiency is a major concern, especially for vans used in remote areas or for long-distance travel. Van air conditioners c...

View MoreAlthough the initial investment for a Parking Truck Air Conditioner might seem higher than a conventional system, the long-term savings quickly add up. With fuel prices continuing to fluctuate, idling for air conditioning can consume several liters of fuel per hour. By contrast, battery-powered systems consume minimal energy while keeping the cabin cool for hours. This substantial savings on fuel costs across a fleet of trucks.

Moreover, many countries and regions have introduced anti-idling laws to reduce emissions. A Parking Truck Air Conditioner helps operators comply with such regulations while avoiding fines and penalties. Over the product's lifespan, its cost-effectiveness lies in its ability to reduce both operational costs and environmental impact, all while improving driver rest conditions.

Safety is a crucial aspect when evaluating any Truck Air Conditioning system. Improper installation, poor quality components, or lack of safety features can issues ranging from overheating to fire hazards. Therefore, both drivers and manufacturers must pay attention to the safety design and operation of these systems.

A reliable Truck Air Conditioning unit should have built-in protection against overvoltage, short circuits, and overheating. Many models now come with automatic shut-off features that activate if internal temperatures exceed safe levels or if battery levels drop too low, preventing damage to the vehicle's electrical system.

Ventilation safety is also important. The air conditioning unit should allow for proper air circulation and filtration to maintain healthy cabin air quality. Filters should be easy to clean or replace, ensuring that dust, allergens, or other airborne particles do not accumulate and affect the driver's health.

Another safety element involves installation. A Truck Air Conditioning system should be securely mounted, with all wiring correctly insulated and placed to avoid movement or damage while the truck is in motion. Professional installation is often recommended to avoid wiring errors or mounting issues that could compromise safety.

For manufacturers, producing a high-quality Truck AC system involves balancing performance, durability, safety, and energy efficiency. Several technical and design aspects must be considered to meet user expectations and regulatory standards.

Component quality is essential. Compressors, condensers, evaporators, and fans must be durable enough to withstand long operating hours in variable weather and road conditions. Using corrosion-resistant materials and heat-tolerant components ensures longevity and consistent performance.

Second, energy efficiency must be built into the system. Since many parking AC units operate on battery power, optimizing power consumption without sacrificing cooling effectiveness is critical. This includes selecting low-draw motors, using efficient cooling cycles, and incorporating smart controllers that regulate temperature based on cabin conditions.

Third, user-friendly interfaces are important. Drivers should be able to operate the Truck AC system intuitively, with clear controls and readable displays. Options such as remote operation, digital timers, and memory settings enhance usability and comfort.

Additionally, noise levels should be minimized. A quieter unit contributes to better rest for the driver during breaks. Design improvements in fan blades, insulation, and vibration damping help achieve a low-noise output.

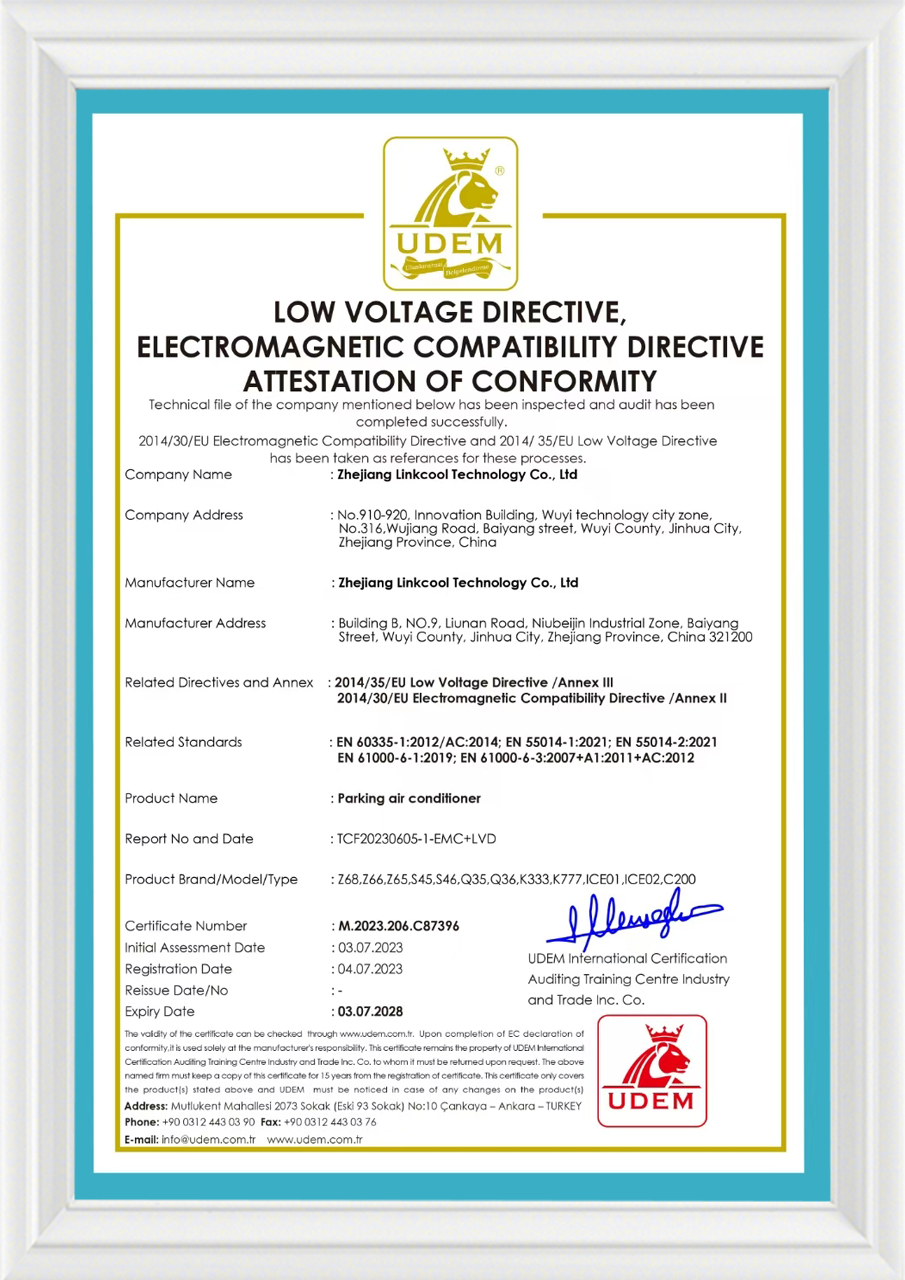

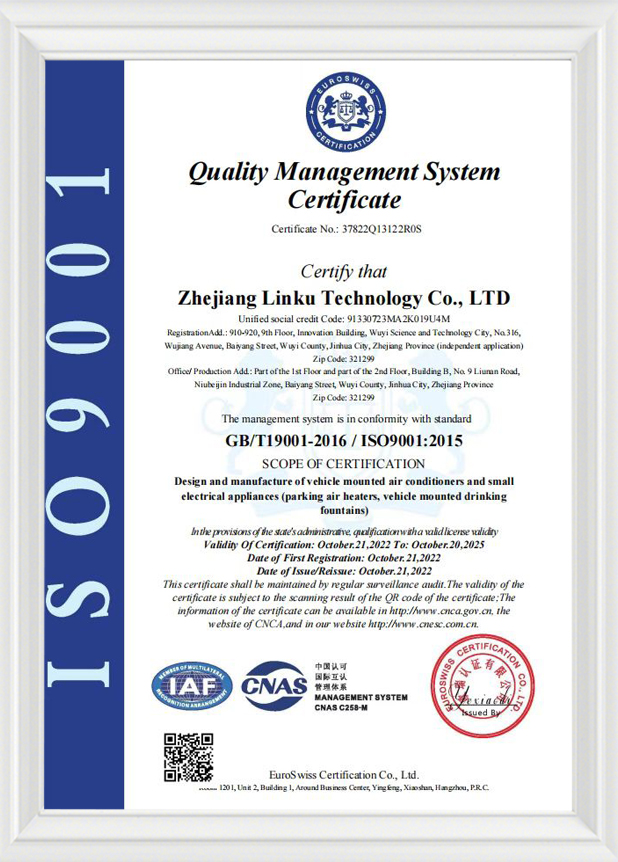

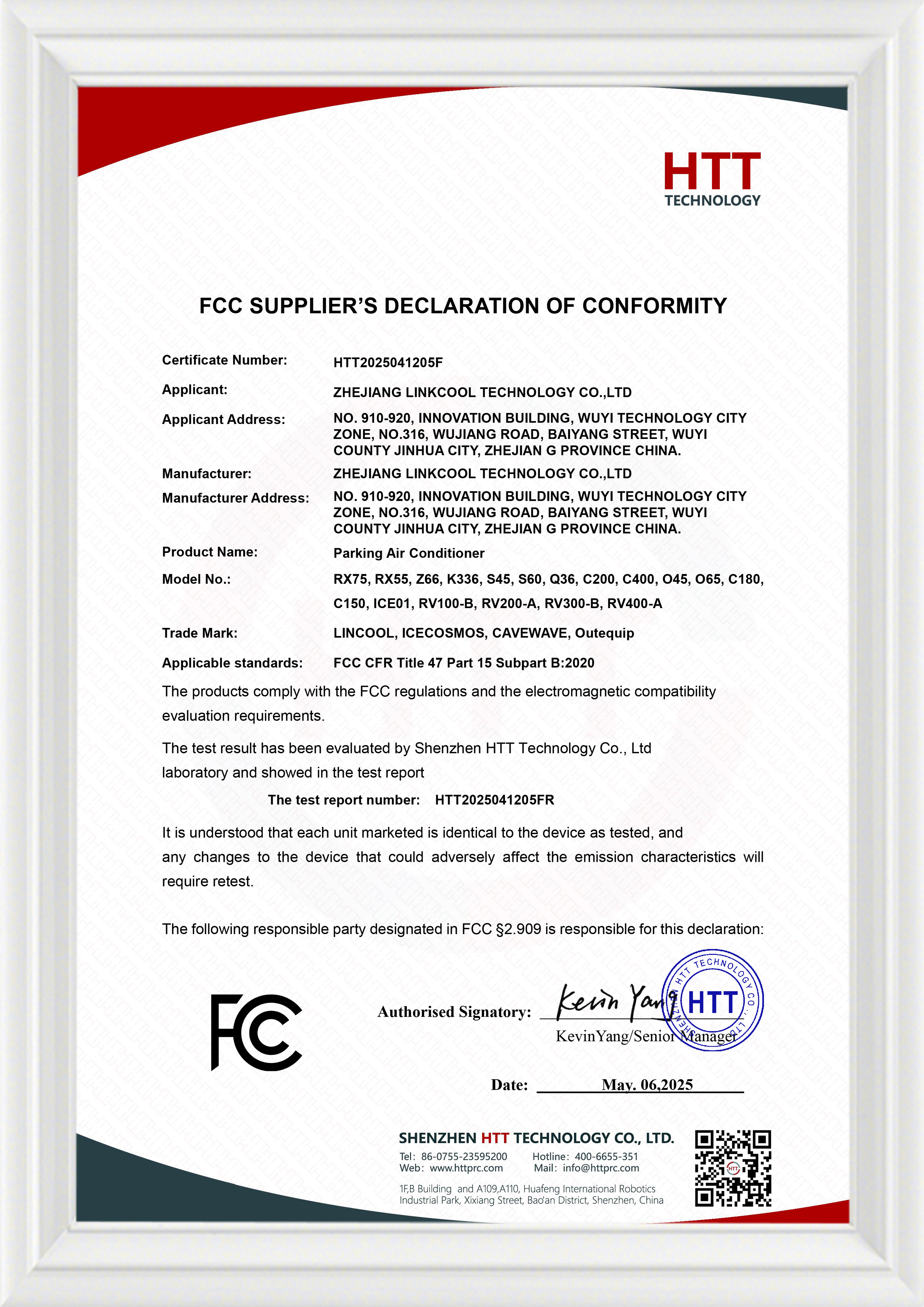

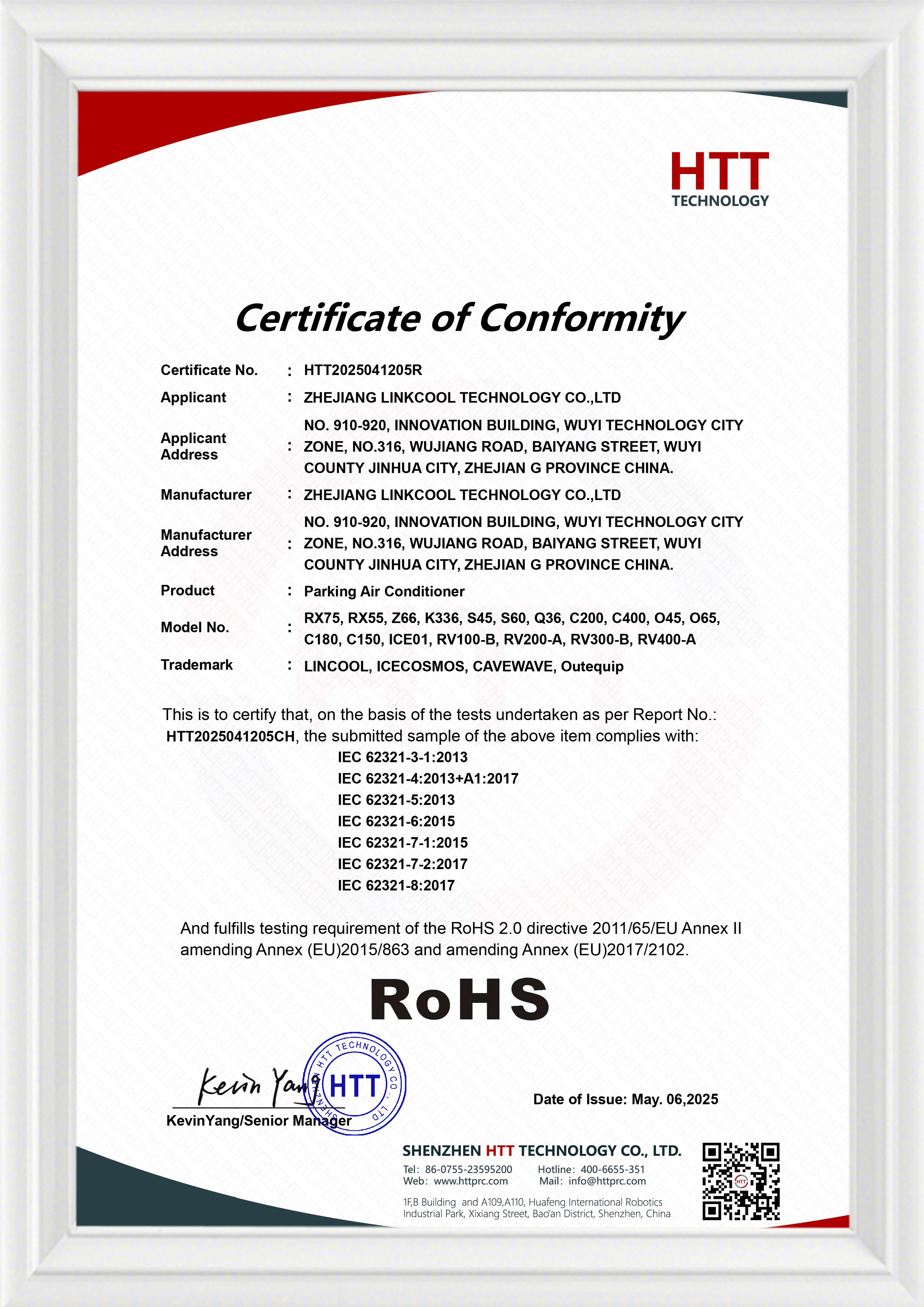

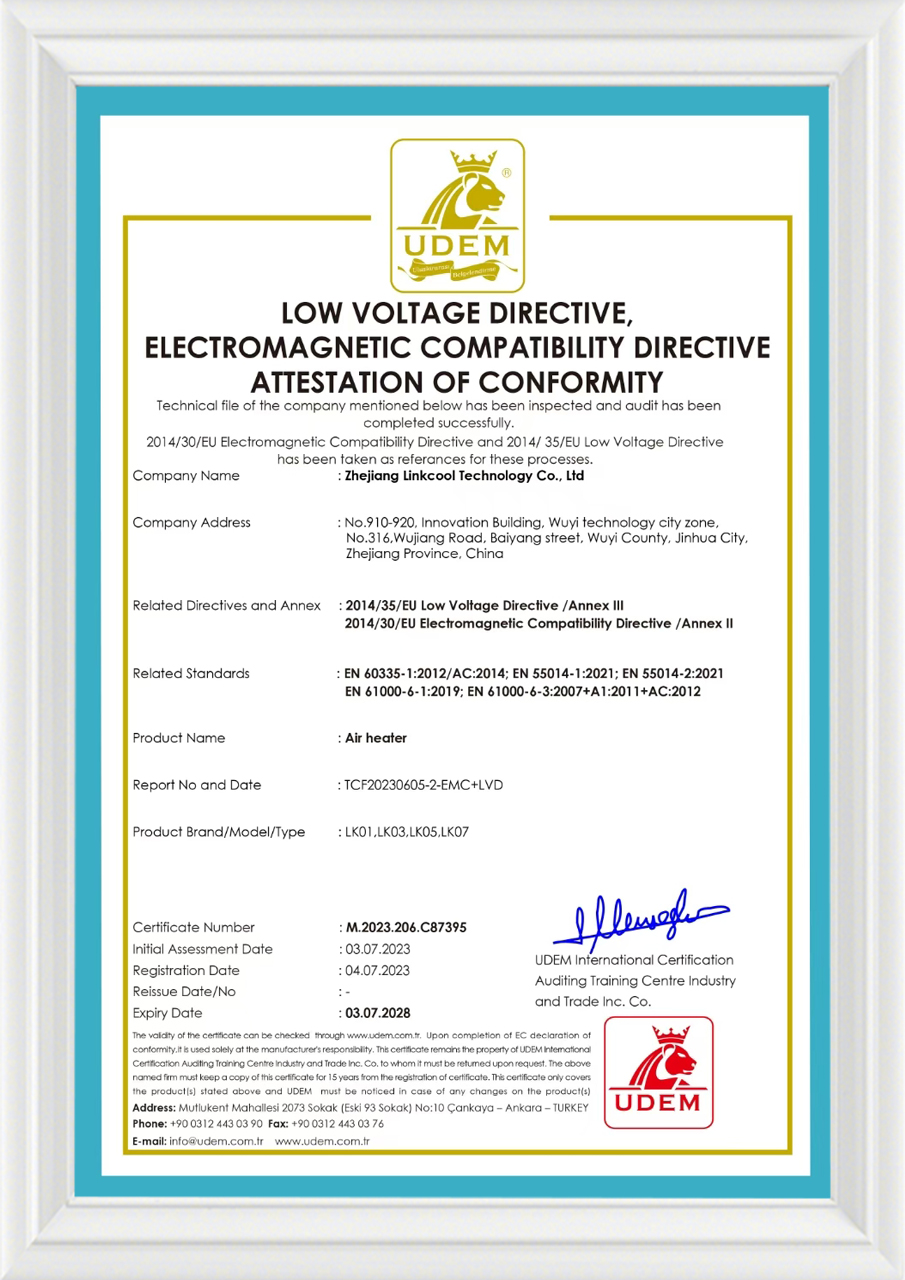

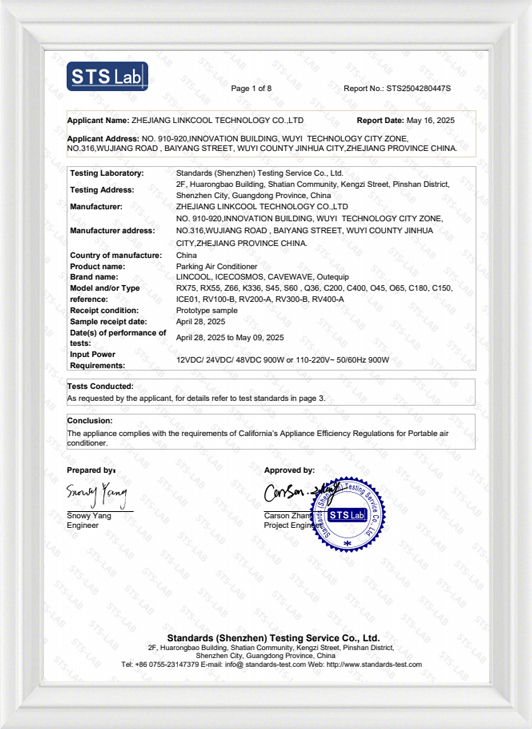

Lastly, compliance with safety and emissions standards is vital. This includes meeting local and international regulations concerning refrigerant use, electrical safety, and environmental performance.

Producing a competitive and reliable Truck AC system means taking a comprehensive approach that covers materials, efficiency, usability, and regulatory compliance—ensuring the product meets the real-world demands of both fleet managers and individual drivers.