Camper air conditioners are compact cooling units designed for mobile living environments, such as RVs, caravans, and camper vans. Their structural design influences performance, durability, and ease of installation. Proper attention to design details ensures that the unit functions effectively while fitting the limited space available in mobile settings.

The outer housing of a camper air conditioner provides physical protection for internal components while maintaining a lightweight and compact form. Typically, housings are made from durable plastics or coated metals, which resist vibration and minor impacts during travel. The housing design must consider:

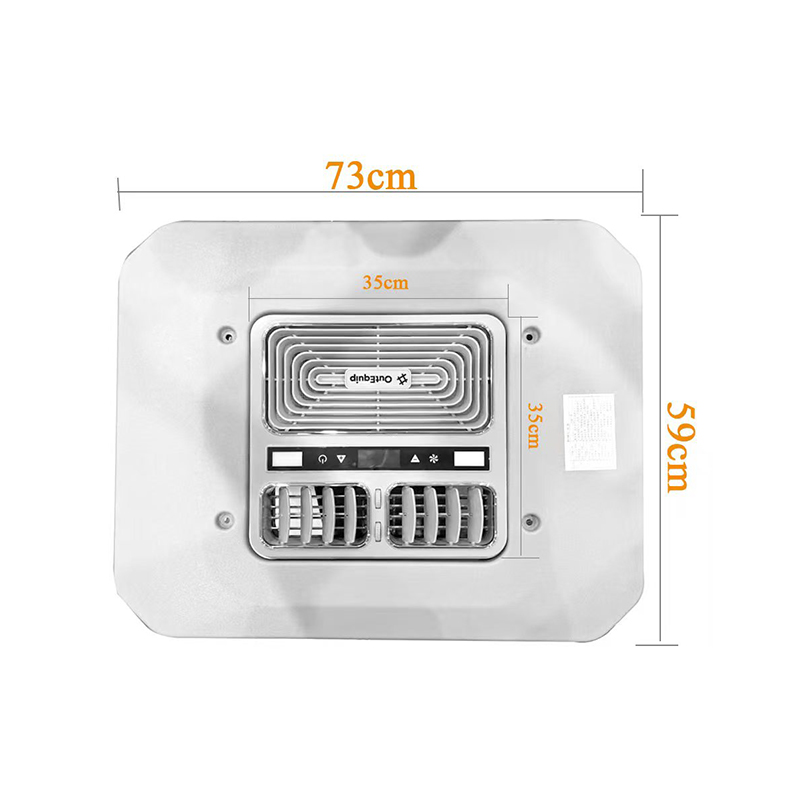

Dimensions and weight: Compact dimensions allow installation on roofs, walls, or ceilings without affecting mobility or interior space.

Airflow openings: Strategic placement of intake and exhaust vents ensures proper air circulation.

Sealing and insulation: Effective seals prevent water intrusion and reduce noise from fans and compressors.

By prioritizing a balanced combination of durability, size, and weight, the housing supports both operational efficiency and user convenience.

The core components of the air conditioner include the compressor, condenser, evaporator, and expansion valve. The structural arrangement of these parts affects both cooling efficiency and maintenance accessibility. Key design considerations include:

Efficient structural layout allows the air conditioner to perform reliably even in confined mobile spaces while simplifying routine maintenance tasks.

Airflow management is critical to ensure uniform cooling and reduce energy consumption. The unit must circulate air within the camper efficiently while venting heat externally. Design considerations include:

Fan selection: Axial or centrifugal fans are chosen based on airflow requirements and noise levels.

Ducting and vents: Properly sized ducts and vents prevent hot spots and maintain consistent temperatures.

Heat dissipation: External condenser placement and adequate spacing allow effective heat release.

Effective airflow and ventilation design enhance the comfort level inside the camper while supporting energy-efficient operation.

Camper air conditioners typically operate on 12V or 24V DC power, sourced from batteries or vehicle alternators. The electrical and control system design ensures safe, reliable operation:

Circuit protection: Fuses and breakers prevent damage from overcurrent or short circuits.

Control panel placement: Easily accessible controls improve usability during travel.

Energy management: Integration with battery monitoring systems allows optimized power usage.

Well-designed electrical systems reduce the risk of component failure and support consistent cooling performance.

|

Structural Element |

Design Considerations |

Purpose |

|

Outer housing |

Dimensions, weight, airflow openings, sealing |

Protection, mobility, noise reduction |

|

Cooling components |

Placement, vibration control, maintenance access |

Efficient heat transfer and service convenience |

|

Airflow and ventilation |

Fan type, ducting, heat dissipation |

Uniform cooling and energy efficiency |

|

Electrical and control |

Circuit protection, control panel, energy management |

Safe operation and optimized power usage |

|

Mounting and supports |

Roof brackets, vibration isolators, fastening points |

Stability and reduced structural stress |

Additional Considerations

Other structural factors may include:

These considerations ensure the air conditioner remains functional, reliable, and user-friendly over time.